What we do:

Our company is a specialist in 3D printing solution (providing all services in relation to printing: starting from 3D design, workflow design, right through to production preparation.)

During our 20 years spent in the film and music industry we have come across several products which could have been used more easily, safely or logically if there had been an accessory.

About us

It is precisely this that led us to engage in 3D printing

We have an abundance of new product ideas, which we would like to turn into reality to see how they work. 3D printing is the perfect manufacturing process for this: it works well for small quantities (1-2 pieces per prototype) or large scale industrial production.

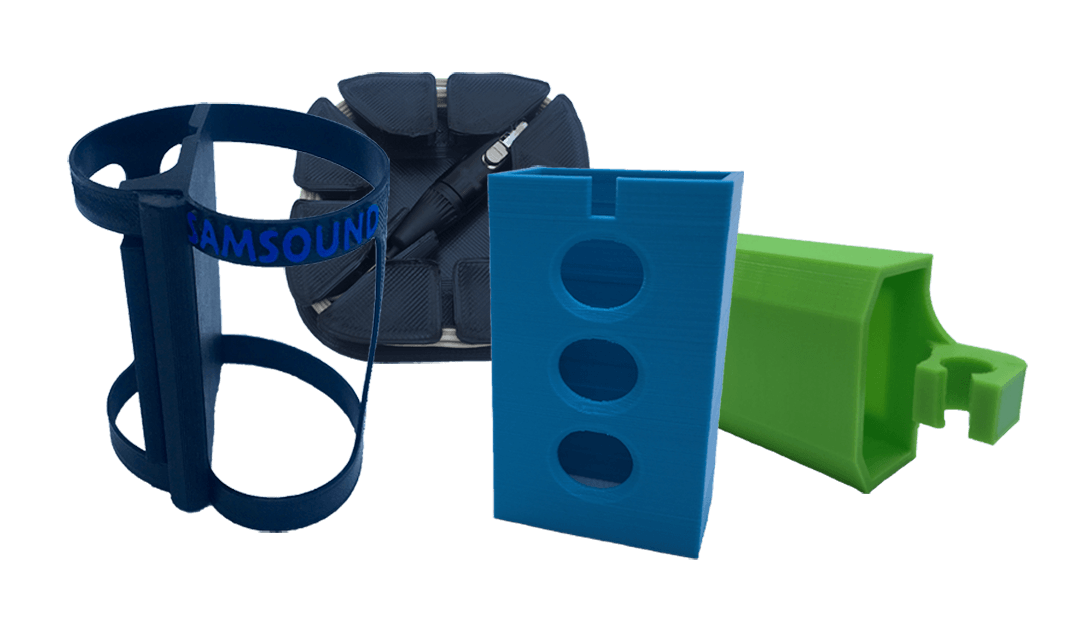

Our initial product range offers useful and handy solutions for film sound- and live sound professionals. We are striving to widen the product range and put 3D printing solutions to use.

We also manufacture battery adapter plates for various powertool brands, accessories for kids toys, bespoke masks, handy accessories for use at home or in the workshop.

TECH

About 3D printing technology

3D printers create physical, three dimensional products. This method works opposite to the traditional way of manufacturing, whereby using CNC- or conventional milling machines, layers of the material is being removed from the work piece. In 3D printing the workpiece is built up layer-by-layer.

3D printing technology goes back to the 1980’s, when its inventors filed patents in order to keep this technology for themselves. The current boom in 3D printing is due to some of those patents having expired.

The most common printing technology is „Fused Deposition Modeling” (FDM for short). This technology is based on the principle of melting during which process the filament gets into the printer as a thin thread. The filament is transported by a system of trundles and a DC motor (the extruder stepper motor) into the printhead (hot end), where it gets melted and squeezed onto the build plate. The technology behind 3D printing resembles to the technology of inkjet printing: a miniscule amount of molten filament is being put on the build plate just like ink on paper in inkjet printing.

TECH

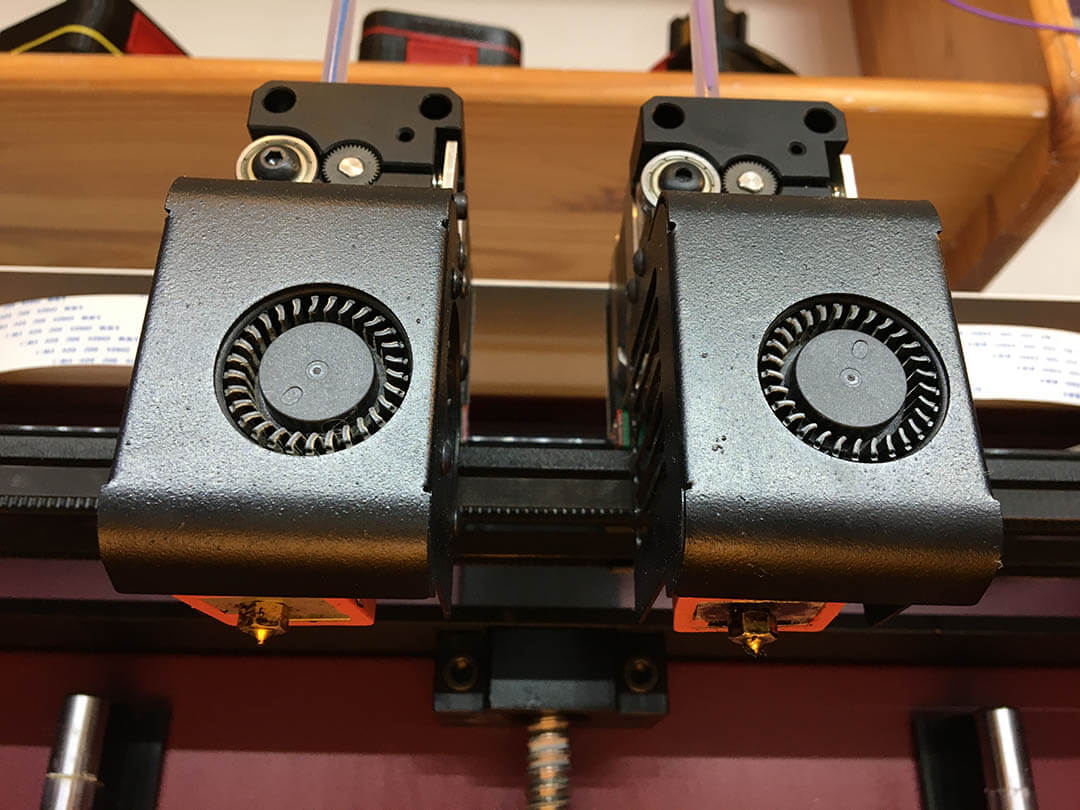

Printers we use

Our printers are multiple award winning models made by the hungarian company „Craftbot”.In order to have an efficient production process we utilise several models, such as:

- Craftbot. maximum print size: 250mmx200mmx200mm layer height: 0,025mm

- Craftbot + maximum print size: 250mmx200mmx200mm layer height 0,025mm

- Craftbot 3XL maximum print size: 420mmx250mmx450mm layer height: 0,025mm

TECH

Printers we use

Our printers are multiple award winning models made by the hungarian company „Craftbot”.In order to have an efficient production process we utilise several models, such as:

- Craftbot. maximum print size: 250mmx200mmx200mm layer height: 0,025mm

- Craftbot + maximum print size: 250mmx200mmx200mm layer height 0,025mm

- Craftbot 3XL maximum print size: 420mmx250mmx450mm layer height: 0,025mm

TECH

About filaments

PlolylacticAcid (PLA for short) is a type of plastic which is made from cornstarch and sugarcane. PLA is difficult to recycle but it is possible to get it to decompose biologically. It is an environmentally friendly material compared to other petrochemically sourced plastics and it emits an odour resemlbing maple syrup when it is melted. In the cooling stage its stiffness changes and it becomes rigid.

Acrylonitrile Butadiene Styrene (ABS for short) is essentially the same material that LEGO bricks are made from. It’s extremely durable, somewhat resilient and it is suitable for many uses. It is shock-resistant and it can stand heat well. It dissolves when it gets in contact with acetone (eg: nail varnish remover). It is also millable, paintable and glueable with a suitable adhesive.

The Glycol modified Polyethylene Terephthalate (PETG for short) is a popular 3D filament material. (PETG for short) The glycol modification results in a clearer, less rigid filament with qualities improving ease of use. PETG provides a good middle ground alternate between ABS and PLA. It is more durable and resilient than PLA and during the production process it is easier to handle than ABS.

FilaFlex is a polyurethane based, remarkably elastic filament for 3D printing. Thanks to the elastic filament we can make special pieces from it.

Beyond the above we are confident to mix materials (such as wood, brass, carbon) in order to achieve the right 3D print part.

Frequently Asked Questions

How is the order working?

Like any other webshop! If you have custom wishes, choose our custom orders page. If you have questions about the details of purchase please read our Általános Szerződési Feltételeinket.

Do you have physical shop somewhere?

We have no physical shops, but in our workshop you can pick up the ordered product.

I have some questions, where can I get in touch with you?

You can contact us on our contact page and you can send us a message as well.

Is there any guarantee for the products?

We will get an all- round guarantee for 30 days from the day of purchase.

How can I make a payment?

You can pay by credit card, bank transfer or by PayPal.

What can I order on Custom Orders page?

We can make anything what you can imagine…